What are the benefits of using insulated concrete forms, otherwise known as ICFs and how does it relate to Net-Zero housing?

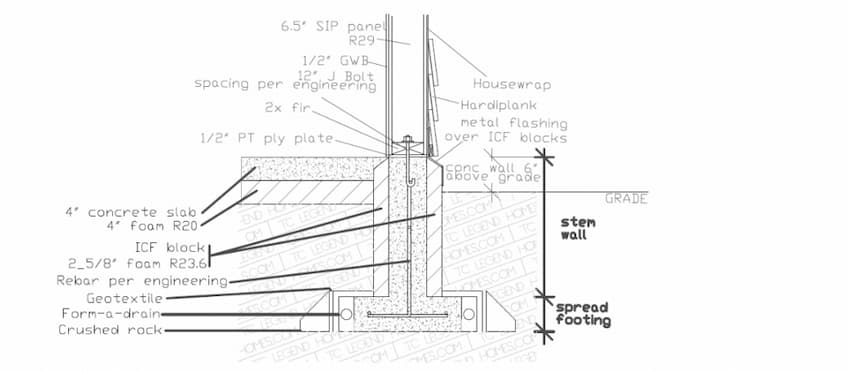

A Net-Zero house is insulated on all (6) sides, and Powerhouse designs with structural insulated panels (SIPs), so we have R-29 SIPs walls all around, R-49 SIPs roof above, and 4” R-20 foam under the slab-on-grade.

Powerhouse Designs: Typical SIPs wall with ICF Foundation

The edge of the slab also needs insulation, otherwise there would be a weak spot and heat would leak out through the slab perimeter, into the stem-walls (which are exposed to the weather).

We solve this problem by pouring the stem-walls into R-24 insulated concrete forms (ICFs) which complete the insulted shell of this Net-Zero home.

Concrete has been poured into foam wall-forms since the ‘80s. The hollow blocks go together like Legos with the required rebar clipped inside, and once full of concrete, the Styrofoam block remains in place performing the job of insulation, and containing concrete while wet. The process is fast and clean, and has lower labor costs compared to traditional concrete forming.

We use NuDura R23.8 ICF blocks to form the stem walls, and retaining walls when we need them. The NuDura blocks are great since they concertina-down to transport. ICF blocks are available in many thicknesses with many variants for different construction requirements. We use 6” walls and usually only order inside-corners, outside-corners and 8’ straight blocks. The NuDura blocks have hard plastic structural strips that accept screws for siding and drywall.

The blocks sit atop the hat-channel that spans the footing form. We use Form-a-Drain footing form when extra drainage is need and like the ICF’s does not need a form-board to be stripped-down after concrete is poured. The Form-a-Drain replaces 8” footer boards, is hollow, and drains water away from the foundation foot.

To protect the foundation, a metal cap/ cladding system is used that wraps the exterior ICF foam from the sill plate downwards below-grade with roofing metal, leaving no visually, or thermally exposed concrete.

ICF’s are great! They perform two functions: (1) insulation, and (2) concrete form, they are a smart solution for our thriving Net-Zero, and increasingly Net-Positive SIPs housing in Washington state!

If you have questions about ICFs or just want to get started designing your new home, contact us!

Edited by Nicole Miller